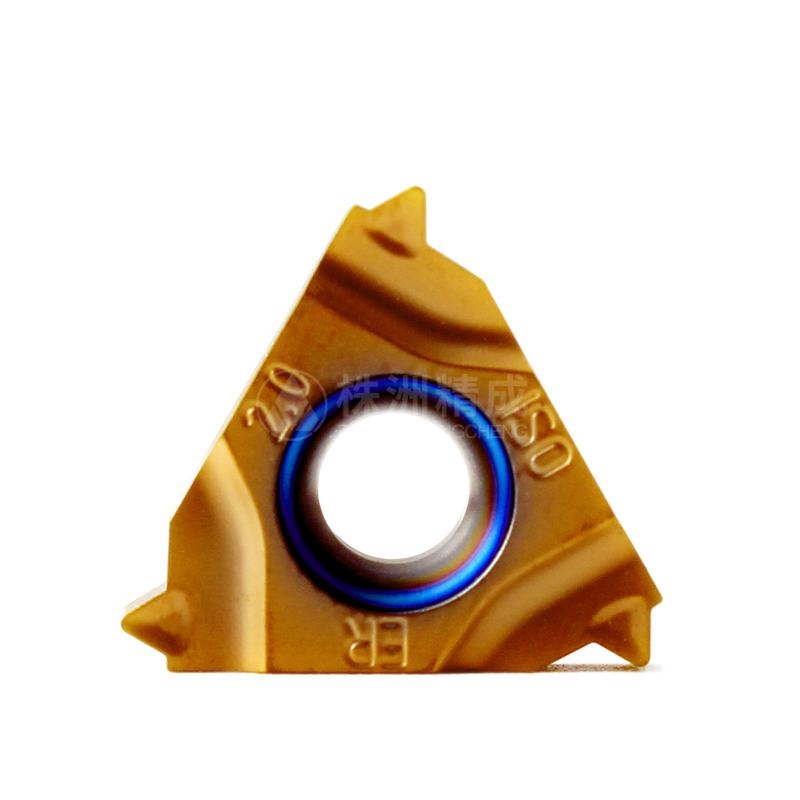

ZCC.CT brand tungsten carbide turning inserts for steel

Short Description:

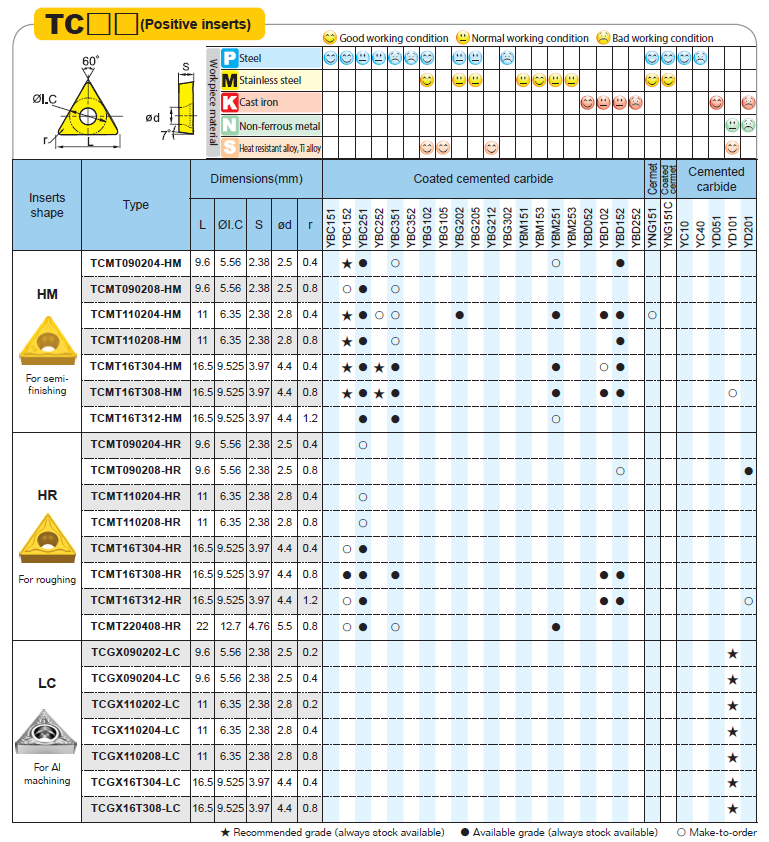

TCMT16T308-HR is one of the positive inserts with hole, suitable for many different types’ materials. Jingcheng Cemented carbide has an extensive selection of CNC threading inserts and tools with high-quality for your choice. We can assist you to choose the suitable cnc inserts according to your situations.

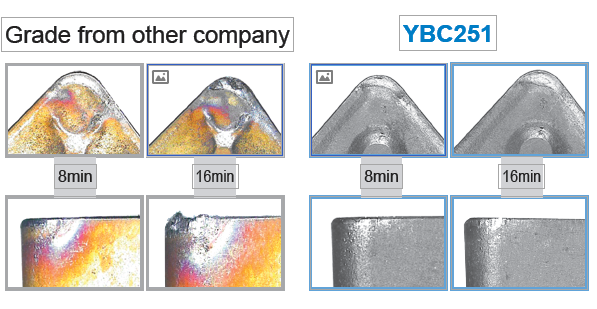

Coated Grade Introduction

YBC251

The substrate with good toughness and high security of cutting edge, in optimal combination with coating composed of MT-TiCN, thick layer of Al2O3 and TiN makes it suitable for steel semi-finishing.

TCMT16T308-HR General chipbreaker for roughing with M-level tolerance, it is suitable for both internal and external roughing of materials such as steel, stainless steel, cast iron, etc.

Features

1. Thanks to the technology of gradient sintering, impact resistance of cutting edge and wear resistance are improved which lead to improved capability of cutting edge against damage.Carbide with special crystal structure improves the Red Hardness of substrate and strengthens heat resistance of insert.

2. TiCN layer acts against abrasion, which leads to the best wear resistance of the flank.

3. Special structure of Al2O3 deposit layer acts as a thermal barrier and strengthens the capability of substrate against plastic deformation under dry and high-speed cutting conditions.

4. Golden surface of TiN can reduce friction and enable easy distinction of the variety of wear.

Test comparison of inserts abrasion

Parameter

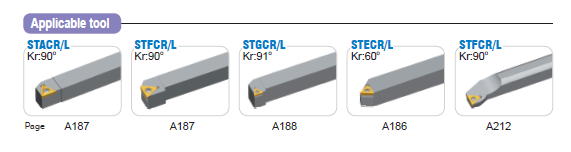

Application

FAQ

Yes and we are doing OEM for many famous brand in the market.

We will send out products in no more than 5 days by courier.

If the type we have in stock, 1box will be OK.

Yes, we can customize for you as your requirements.

First, the workpiece material.

Second, the shape and dimension details.

Third, if you need customized, offer us the drawing will be better.