Tungsten carbide flat strips for woodcutting machine

Short Description:

Cemented carbide strips are mainly made by mixing WC tungsten carbide and Co cobalt powder through metallurgical methods such as powder making, ball milling, pressing, and sintering. The composition content of WC and Co in cemented carbide strips is not consistent for different purposes, and their use range is extremely wide.

Features

Cemented carbide strips have high hardness, good wear resistance, high elastic modulus, high compressive strength, good chemical stability (acid, alkali, high-temperature oxidation resistance), low impact toughness, low expansion coefficient.

Technological Process

Powder making → Formula according to usage requirements → Wet grinding → Mixing → Crushing → Drying → Sieving → Addition of forming agent → Re drying → Preparation of mixture after sieving → Granulation → Pressing → Forming → Low pressure sintering → Forming (blank) → Flaw detection inspection → Packaging → Warehousing

Advantages

1. Various Grades and dimensions with virgin material.

2. Fast Lead time with stable and good quality.

3. Customized size are acceptable

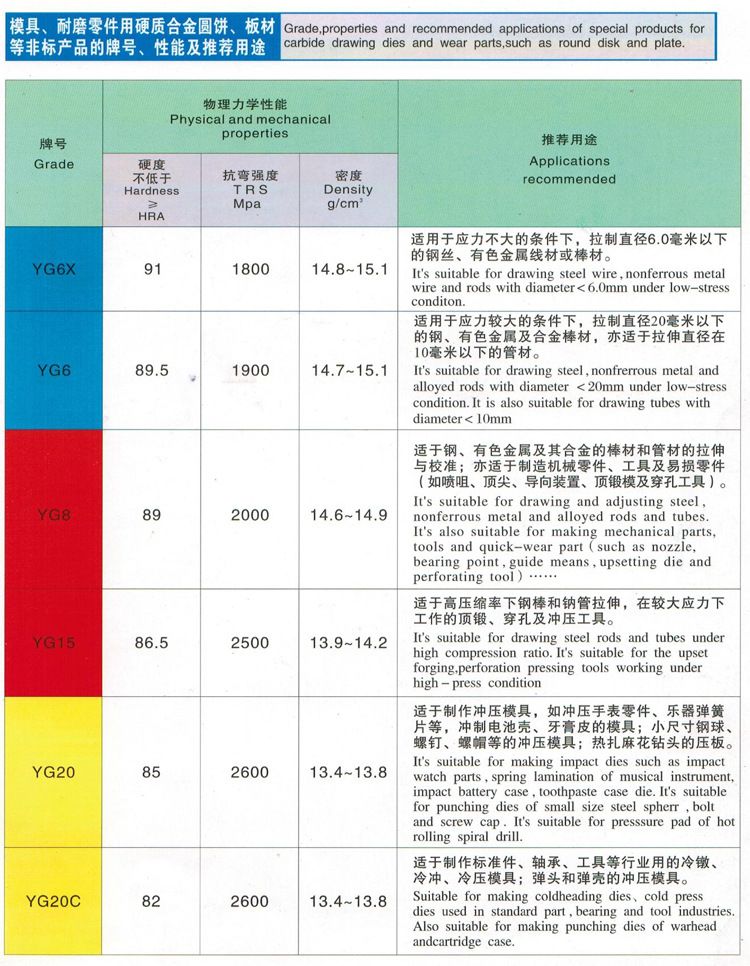

Grade recommend

Specification

| Type(T*W*L) | Tolerance of T(mm) | Tolerance of W(mm) | Tolerance of L(mm) |

| 1*(2-5)*L | T≤7.0

T +0.2~+0.5

T>7.0 T +0.2~+0.6 |

W≤30

W +0.2~+0.6

W>30 W +0.2~+0.8 |

L<100

L 0~+1.0

L≥100 L 0~+2.0

L=330 L 0~+5.0 |

| 1.5*(2-10)*L | |||

| 2*(4-15)*L | |||

| 3*(3-20)*L | |||

| 4*(4-30)*L | |||

| 5*(4-40)*L | |||

| 6*(5-40)*L | |||

| (7-20)*(7-40)*L | |||

| Besides the specifications mentioned above, special specifications can be supplied according to your requirements. | |||

FAQ

Yes, we can customize for you as your requirements.

Generally it is 3~5 days if the goods are in stock; or it is 10-25 days if the goods are not in stock, depending on order quantity.

Generally we don't provide free samples. But we can deduct sample cost from your bulk orders.

Always a pre-production sample before mass production; Always final Inspection before shipment .