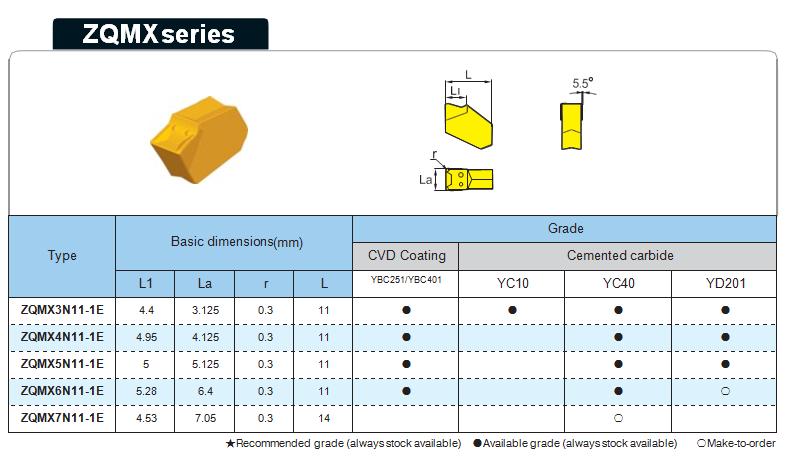

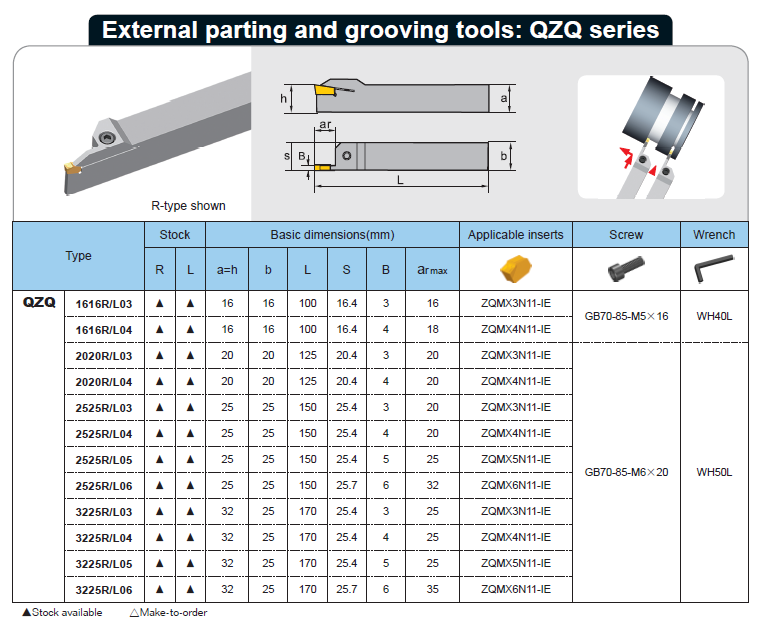

Supplementary series parting and grooving inserts

Short Description:

ZQMX6N11-1E is one type of unique and professional structure design of parting inserts. Jingcheng Cemented carbide has an extensive selection of CNC turning inserts and tools with high-quality for your choice. We can assist you to choose the suitable turning inserts according to your situations.

Coated Grade Introduction

YBG302

The combination of nc-TiAlN coating and tough cemented carbide substrate, which integrates security and wear resistance, makes it suitable for parting and grooving of various materials.

ZQMX6N11-1E Inserts of the same edge with can work with corresponding tool holders to satisfy the requirements of external, internal and surface grooving and turning by using minimum numbers of inserts and tool holders, effectively reducing cost of tool storage and management.

Features

1. A special flank structure is designed to reduce cutting resistant force by 20% and diminish vibration, which improves the surface quality.

2. A special edge design requires less rigidity of machine. It can be used on low power machines.

3. Special coating techniques make inserts smooth, which leads to low friction and unobstructed chip flow.

Unique coating w structure closely

4. Unique coating with nano structure closely integrates with substrate, ensuring higher hardness and toughness.

5. Excellent thermal stability and chemical stability can effectively protect cutting edge.

Parameter

Application

FAQ

Yes and we are doing OEM for many famous brand in the market.

We will send out products in no more than 5 days by courier.

If the type we have in stock, 1box will be OK.

Yes, we can customize for you as your requirements.

First, the workpiece material.

Second, dimension details:drill diameter, shank type, drilling depth, flute length and total length, cooling mode.

Third, if you need customized, offer us the drawing will be better.