Solid Carbide Drills General Machining Boring Tool

Short Description:

GD series General-purpose twist drill versatile, for high efficiency machining in a variety of material e.g. P(steel), M(Stainless steel), K(cast iron).We have extensive practical experience in this field and we can offer you many types as you need. Our company also can customized the tungsten carbide drills ( drill bits, carbide burr and so on) as your requirements.

product Introduction

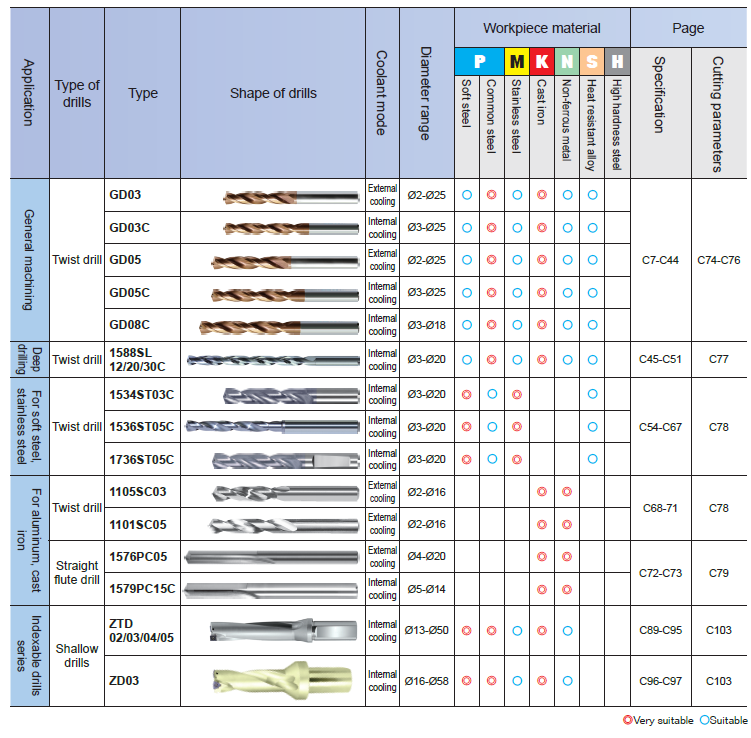

Boring tools over view

| Drills | Solid carbide drills |

| Indexable shallow drills | |

| Reamers | Solid carbide reamers |

| Threading cutters | Solid carbide threading cutters |

| Solid carbide threading mills |

Drilling tools overview

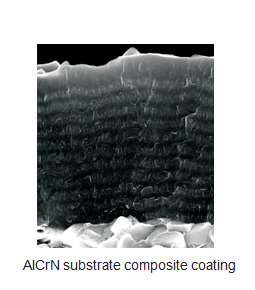

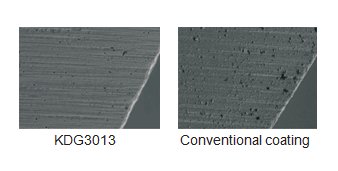

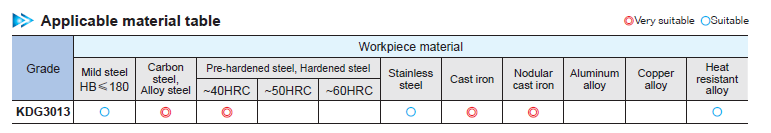

Coated grade: KDG3013 New AlCrN substrate composite coating, with excellent abrasion resistance and bonding resistance, improves the stability of the insert edge. Unique coating after-treatment technology effectively reduces the cutting resistance for smoother chip evacuation and higher security.

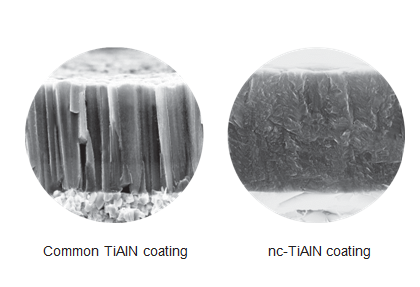

KDG303: Ultra-fine carbide substrate with high strength, toughness and wear resistance, in combination with nano-structured nc-TiAlN coating aiming at optimizing drilling operations, makes sure the tools have very high toughness and hardness. Unique coating technology gives the tools smooth surface and excellent wear resistance, and outstanding thermal stability and chemical stability provide effective protection for the cutting edge.

Features

GD series have a wide applications range. There are some features as the following:

1. Versatile, for high efficiency machining in a variety of material e.g. P(steel), M(stainless steel), K (Cast iron).

2. Linear cutting edge with high strength. Optimized drill point structure for better cutting performance.

3. Simulation in combination with testing for superior overall performance.

4. Professional after treatment for coating ensures low-resistance high-efficiency machining.

5. Double edge-line design for improved machining stability.

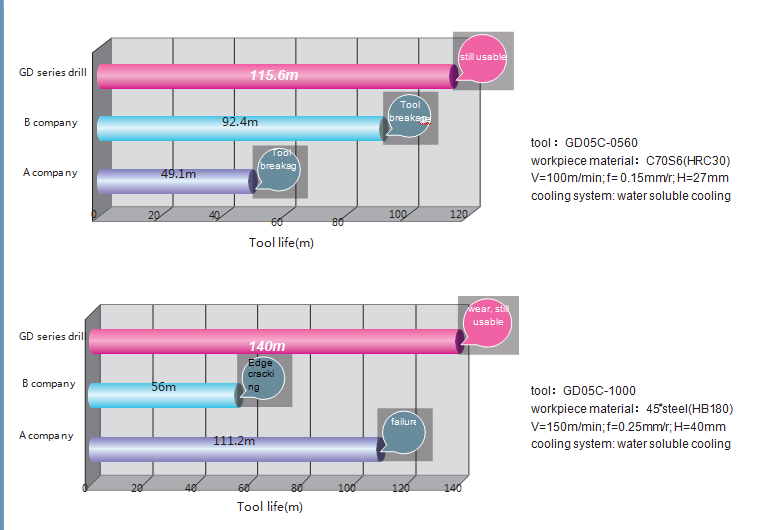

Test comparison of inserts abrasion

Long and stable tool life

Outstanding machining precision

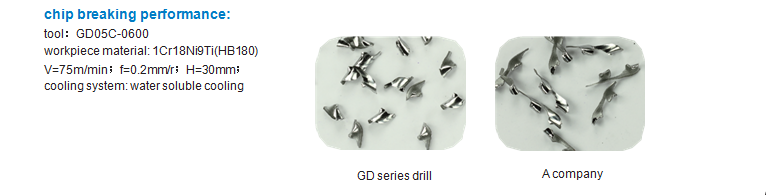

Excellent chip breaking performance

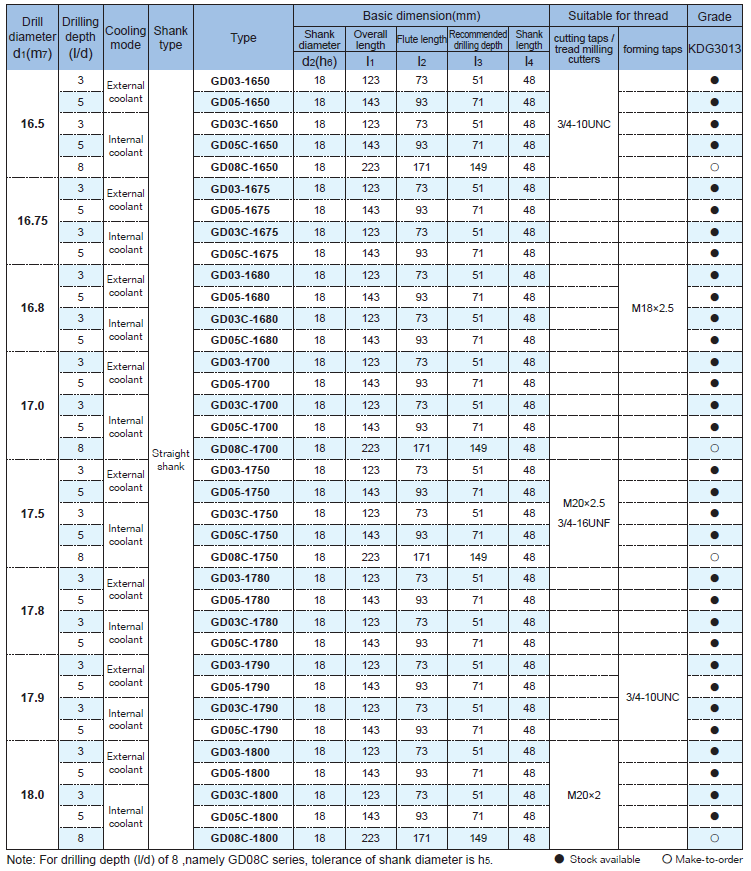

Parameter

Application

FAQ

The main different is processing requirements: end mills are for milling, while drill bits are for drilling and reaming. Although in some cases, the milling cutter can also drilling, but it is not the mainstream.

If the type we have in stock, any quantity will be OK.

Yes, we can customize for you as your requirements.

First, the workpiece material.

Second, dimension details:drill diameter, shank type, drilling depth, flute length and total length, cooling mode.

Third, if you need customized, offer us the drawing will be better.