Solid Carbide Ball Nose End Mill

Short Description:

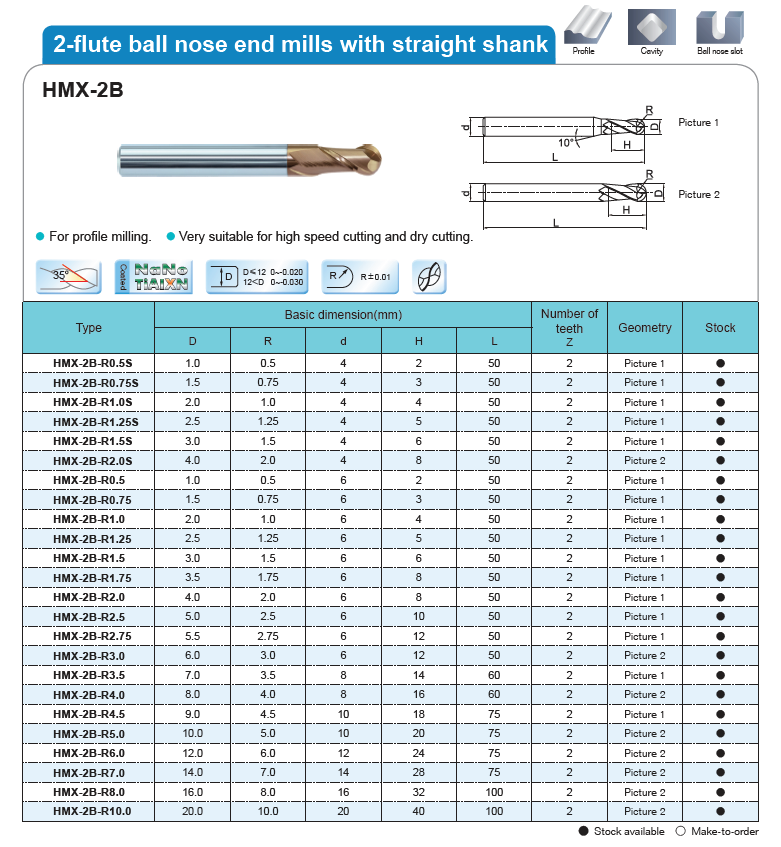

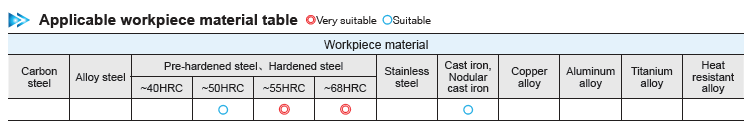

HMX Series 2-flute ball nose end mills with straight shank suitable for high-hardness steel machining.We have extensive practical experience in this field and we can offer you almost types of solid carbide end mills.

HMX series Introduction

Lattice heterogeneous coating added with special elements, with high hardness and excellent high temperature oxidation resistance, more suitable for high hardness materials and high speed machining

unique cutter structure, properly designed chipbreaker, for outstanding cutting performance.

Orange red coating allows for better wear observation.

Special after treatment greatly reduces friction, for smoother chip evacuation and superior surface quality.

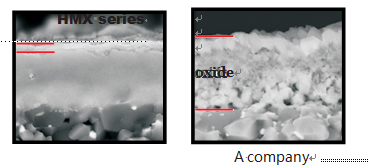

Perfect high temperature oxidation resistance:

After oxidation at 1100 ° C, HMX series cutter coating only has a very thin oxide layer, while the similar products of Company A has completely oxidized.

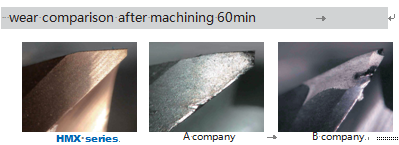

tool: HMX-4E-D10.0

workpiece material: SKD11(62HRC)

cutting speed: 100m/min

feed per tooth: 0.2mm/r

axial depth of cut: ap=10mm

radial depth of cut: ae=0.3mm

cooling system: air cooling

Parameter

Application

FAQ

According to the shape we have so many types , such as flattened end mill, radius end mill, ball nose end mill, high-feed-rate end mill, long neck end mill, tiny head end mill and so on.

The main different is processing requirements: end mills are for milling, while drill bits are for drilling and reaming. Although in some cases, the milling cutter can also drilling, but it is not the mainstream.

If the type we have in stock, any quantity will be OK.

Yes, we can customize for you as your requirements.

First, the workpiece material.

Second, the shape and dimension details:shank diameter, flute diameter, flute length and total length, the number of the teeth.

Third, if you need customized, offer us the drawing will be better.