High quality ZCC.CT tungsten carbide inserts for turning tools

Short Description:

TNMG220408-PM is a specific type of indexable carbide inserts widely used in machining operations, especially turning applications. Its unique coating, precise size and chip control features make it a popular choice for a variety of machining applications.

Coated Grade Introduction

YBC251 is a unique coating with excellent wear resistance and heat resistance. It consists of a combination of titanium carbonitride (TiCN) and aluminum oxide (Al2O3) layers. This coating helps to extend tool life and improve the performance of the insert under various cutting conditions.

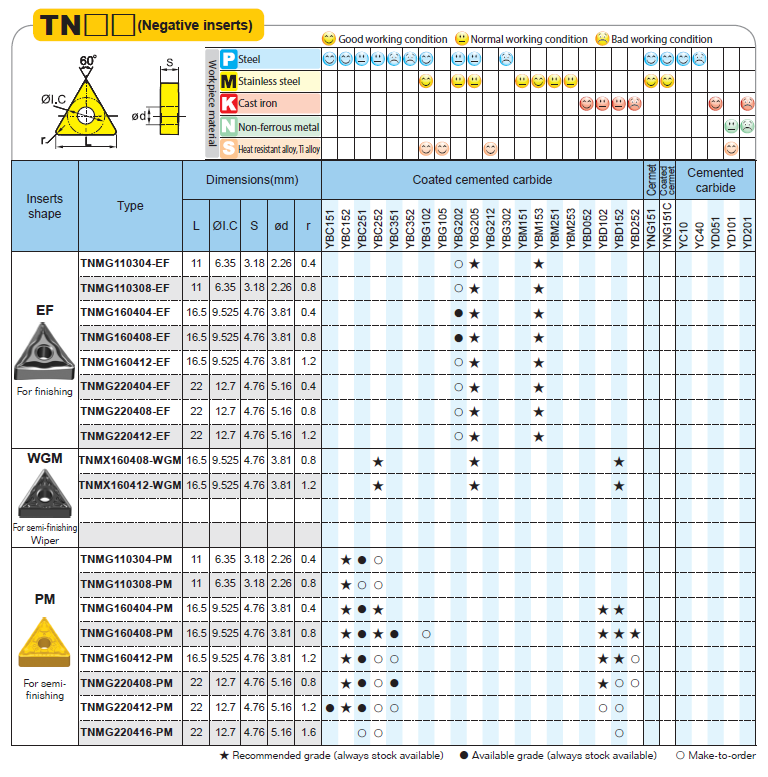

TNMG220408-PM Inserts fall under certain standard naming conventions. "TNMG" indicates the shape and size of the blade, and "220408" indicates the size details of the blade. The PM in the name stands for Precision Machining, indicating that the insert is designed for precision cutting operations. This type is commonly used in general turning and facing. Recommended chipbreaer for semi-finishing of P-type materials Double-sided chipbreaker with M-level tolerance has higher strength of cutting edge than chipbreaker DM. It is suitable for semi-finishing under unstable working conditions as well as machining cast iron with small cutting forces.

Features

1. Inserts shape: This is a negative blade with an 85 degree diamond shape. This shape provides strength and durability.

2. Inserts size: 220408 number indicates the blade size. 22 indicates the side length of the blade (1/8 inch), 04 indicates the thickness of the blade (1/16 inch), and 08 indicates the radius of the cutting edge of the blade (1/64 inch).

3. Application: This blade is suitable for cutting various materials, such as steel, cast iron, stainless steel and non-ferrous metals.

4. Cutting parameters: The specific cutting speed, feed speed and cutting depth parameters need to be determined according to the nature of the material being cut and cutting conditions.

5. Inserts material: carbide is a kind of high hardness material, with good wear resistance and thermal deformation resistance, suitable for high-speed cutting.

Please note that the specific performance and application of the TNMG220408 may vary slightly by inserts’ brand and model.

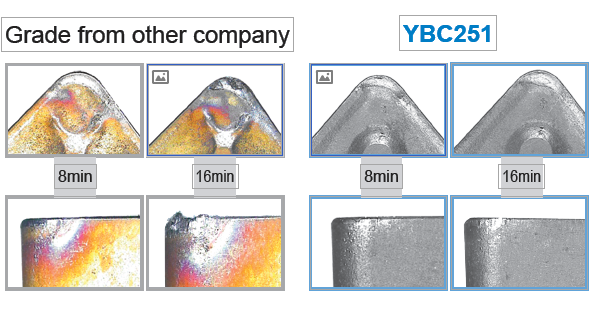

Test comparison of inserts abrasion

Parameter

Application

FAQ

Yes and we are doing OEM for many famous brand in the market.

We will send out products in no more than 5 days by courier.

If the type we have in stock, 1box will be OK.

Yes, we can customize for you as your requirements.

First, the workpiece material.

Second, the shape and dimension details.

Third, if you need customized, offer us the drawing will be better.