High Quality Customized Cemented Tungsten Carbide Plate/Sheet

Short Description:

Tungsten carbide plate is a plate made of cemented carbide. Cemented carbide, also known as hard alloy material or tungsten steel, is a material made of tungsten, cobalt, carbon and other metal powders sintered at high temperature. Its main feature is that it has the advantages of high hardness, high strength and good wear resistance.

Application

Cemented carbide plates are widely used in machining, mining, oil drilling and other fields. In machining, carbide plates are often used as cutting tools, such as blades or heads of knives. Its excellent hardness and wear resistance enable it to maintain stable cutting performance under high-speed cutting and heavy-duty operations.

In mining, carbide plates are often used as crushing and grinding components for drill bits or drilling/breaking equipment. Its superior hardness and wear resistance enable it to withstand strong impact and wear, prolong service life and improve mining efficiency.

In addition, cemented carbide plates are also used to manufacture wear-resistant parts such as wear-resistant liners for crushers and grinding plates for grinders. In some scenes with high strength and high wear resistance requirements in the industrial field, cemented carbide plates are also one of the indispensable materials.

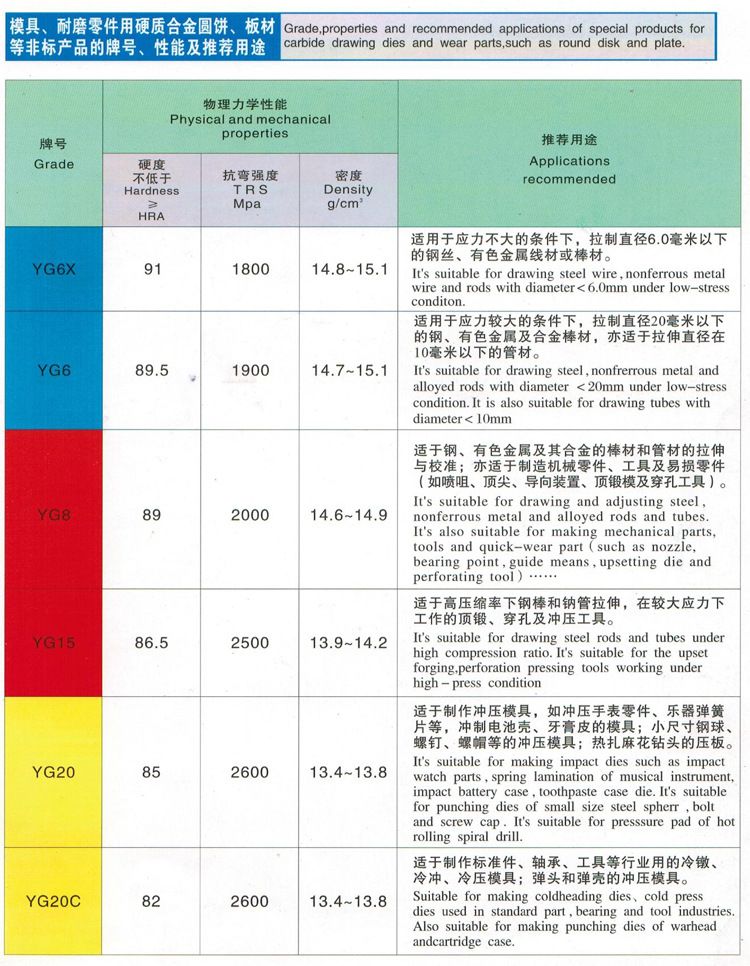

Grade recommend

Specification

| Type |

Blanks Tolerance(mm) |

||

|

L |

W |

H |

|

| 100*100*(1.0-70) |

±2.2 |

±2.2 |

+0.5/+1.5 |

| 105*105*(1.0-70) |

±2.2 |

±2.2 |

+0.5/+1.5 |

| 120*120*(5.0-70) |

±2.2 |

±2.2 |

+0.5/+1.5 |

| 150*150*(5.0-70) |

±2.2 |

±2.2 |

+0.5/+1.5 |

| 200*200*(10-70) |

±2.2 |

±2.2 |

+0.5/+1.5 |

| Besides the specifications mentioned above, special specifications can be supplied according to your requirements. | |||

FAQ

Yes, we can customize for you as your requirements.

Generally it is 3~5 days if the goods are in stock; or it is 10-25 days if the goods are not in stock, depending on order quantity.

Generally we don't provide free samples. But we can deduct sample cost from your bulk orders.

Always a pre-production sample before mass production; Always final Inspection before shipment.