High quality CNC cemented carbide turning inserts

Short Description:

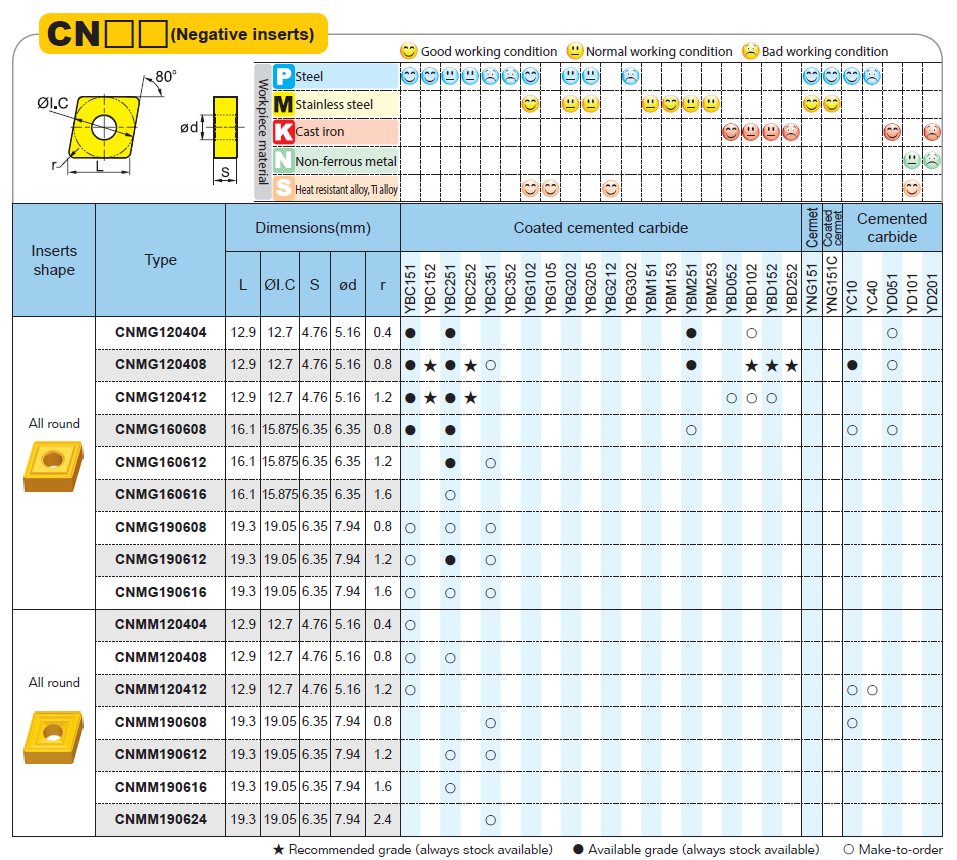

CNMG120408 is a metal turning tool, commonly used in lathe processing and turning process Jingcheng Cemented carbide has an extensive selection of CNC turning inserts and tools with high-quality for your choice. We can assist you to choose the suitable turning inserts according to your situations.

Coated Grade Introduction

YBC151

YBC151 The combination of substrate with excellent wear resistance and coating composed of MT-TiCN, thick layer of Al2O3 and TiN makes it suitable for finishing steel.

CNMG120408-DM is a commonly used turning tool, which is often used in metal processing. The CNMG stands for the blade series, 12 stands for the size and shape of the blade, 04 stands for the thickness, and DM stands for chipbreaker. 04 indicates the cutting edge angle .

Features

1. Wear resistance: CNMG120408 is made of cemented carbide, which has high hardness and wear resistance, and can provide long-lasting service life in high-speed cutting processes.

2. Tool Shape: The CNMG120408 tool is diamond shaped with a pointed cutting edge for turning operations in different directions and angles.

3. Cutting efficiency: Due to the reasonable design of the CNMG120408 tool, the shape of the tip is sharp and the cutting resistance is small. Therefore, it can provide higher cutting efficiency and faster processing speed.

4. Versatility: The CNMG120408 cutter is suitable for turning operations in a variety of metallic materials, including steel, cast iron, stainless steel, aluminum, and more. It can be used for different turning operations such as rough grinding, semi-finish grinding and finish grinding.

In a word, CNMG120408 is a versatile, wear-resistant and efficient metal turning tool for various turning operations and different types of metal material processing. However, specific uses and characteristics may difference between different suppliers or specific processing requirements, so please refer to the detailed specifications and instructions provided by the supplier before purchasing or using the tool. Please note that specific product information (such as insert size, cutting material, coating, etc.) may vary between different suppliers or manufacturers. Before purchasing or using any inserts, read and follow the exact specifications and instructions provided by the manufacturer

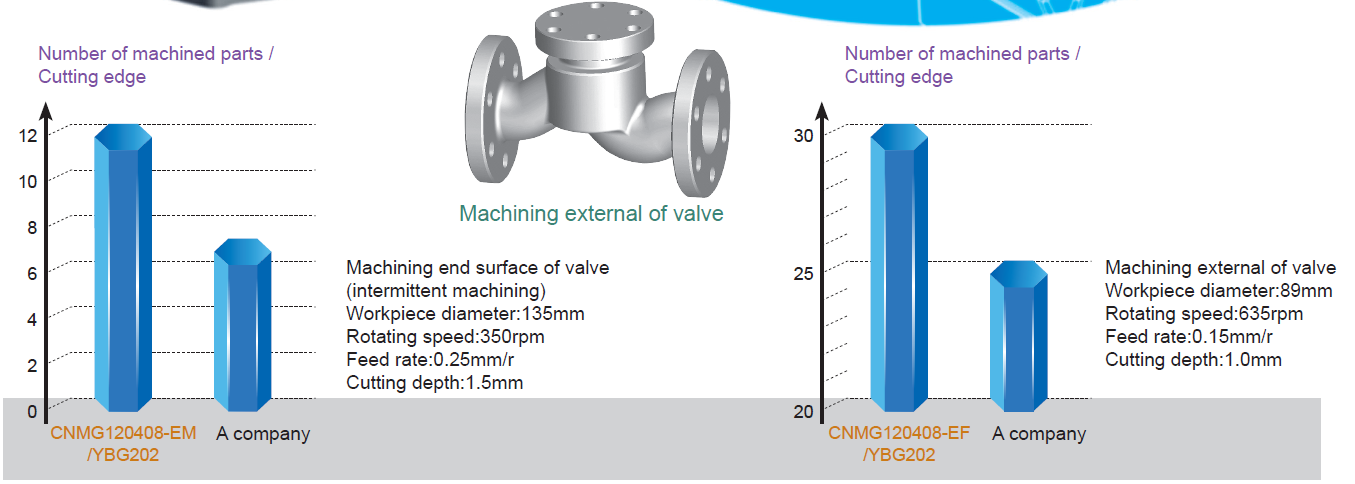

Test comparison of inserts abrasion

Parameter

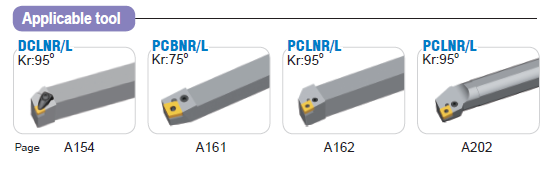

Application

FAQ

Yes and we are doing OEM for many famous brand in the market.

We will send out products in no more than 5 days by courier.

If the type we have in stock, 1box will be OK.

Yes, we can customize for you as your requirements.

First, the workpiece material.

Second, the shape and dimension details.

Third, if you need customized, offer us the drawing will be better.