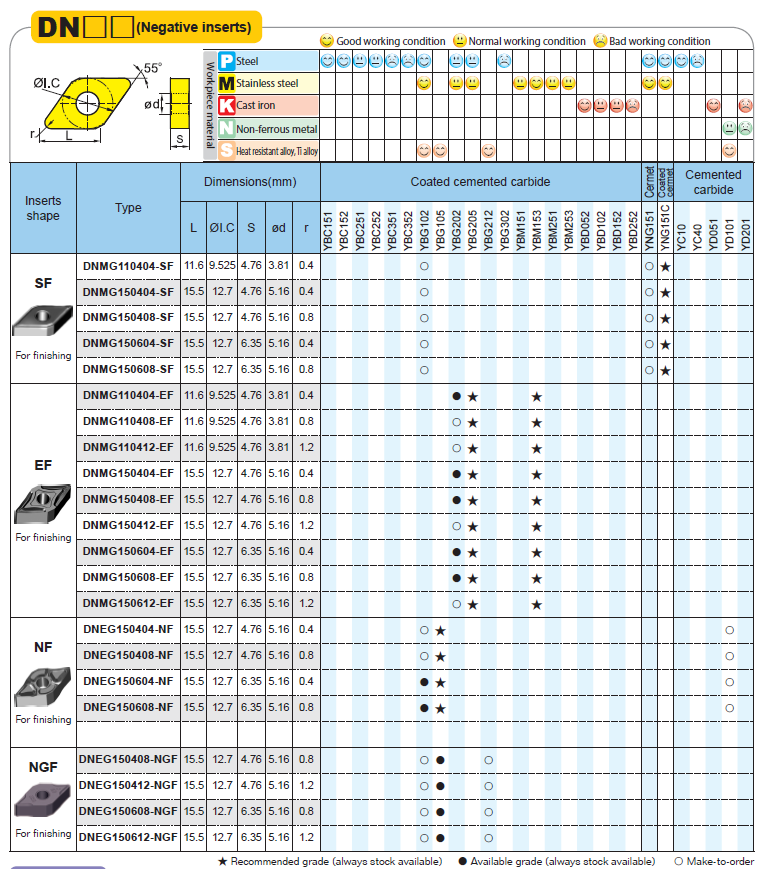

General carbide turning inserts for stainless steel

Short Description:

DNMG150408-EF is a common turning inserts, suitable for turning of steel, stainless steel, cast iron and other materials. Jingcheng Cemented carbide has an extensive selection of CNC threading inserts and tools with high-quality for your choice. We can assist you to choose the suitable cnc inserts according to your situations.

Coated Grade Introduction

YBG205

PVD coating grade for finishing of stainless steel

Suitable for relatively small workpieces which require high surface smoothness.

Superfine TiAlN nano coating added with wear-resistantand heat-resistant rare elements has high hardness and excellent heat-resistance, providing effective protection for the cutting edge. Special coating technology ensures stronger combination of coating and substrate. It is suitable for extra finishing of stainless steel.

DNMG150408-EF has the characteristics of high-quality insert material, replaceable insert design, high cutting efficiency and wide applicability. It is a commonly used turning tool that can meet the turning needs of different materials. At the same time, according to the specific turning requirements, the insert size and other parameters may be adjusted

Features

1. High-quality blade material. DNMG150408-EF adopts high-hardness carbide inserts with good wear resistance and rigidity, which can provide long service life and stable processing performance.

2. Replaceable blade design. The blades of DNMG150408-EF can be easily replaced, which is convenient for tool maintenance and replacement of blades with different requirements.

3. High cutting efficiency. The DNMG150408-EF insert has a reasonable tool geometry and tool edge angle, which can achieve low cutting force and high cutting efficiency, and improve the productivity of turning.

4. Wide application range. DNMG150408-EF is suitable for turning of various materials, including steel, stainless steel, cast iron, etc., with strong adaptability.

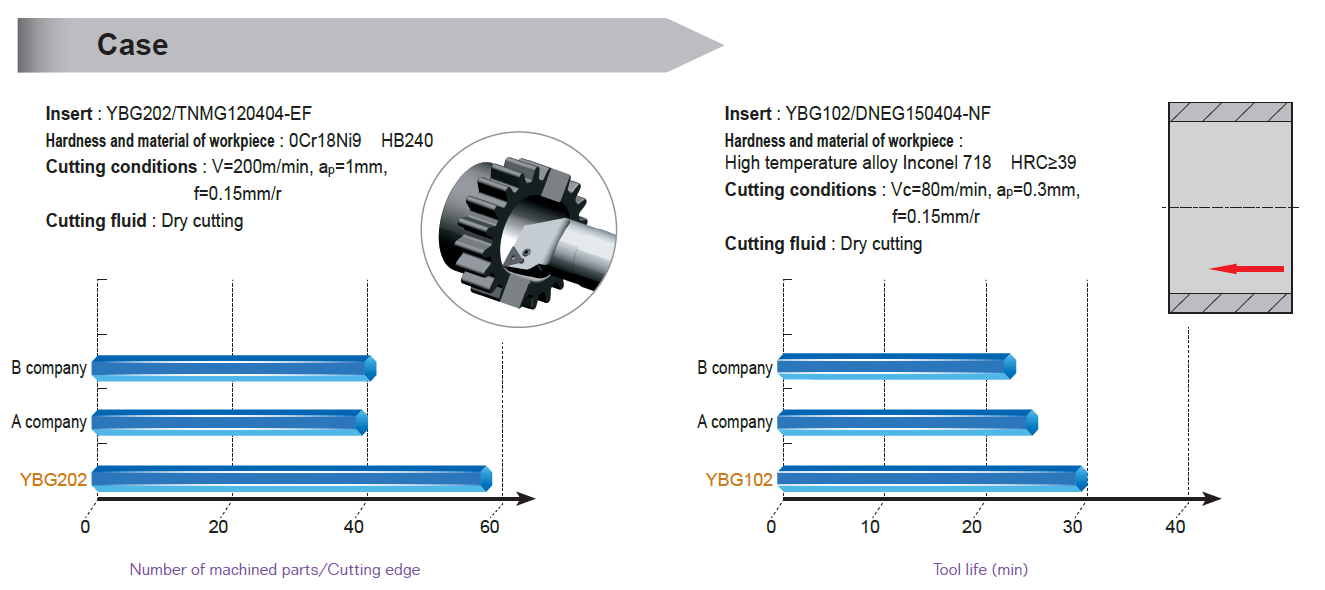

Test comparison of inserts abrasion

Parameter

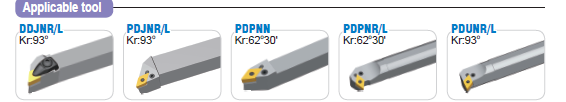

Application

FAQ

Yes and we are doing OEM for many famous brand in the market.

We will send out products in no more than 5 days by courier.

If the type we have in stock, 1box will be OK.

Yes, we can customize for you as your requirements.

First, the workpiece material.

Second, the shape and dimension details.

Third, if you need customized, offer us the drawing will be better.