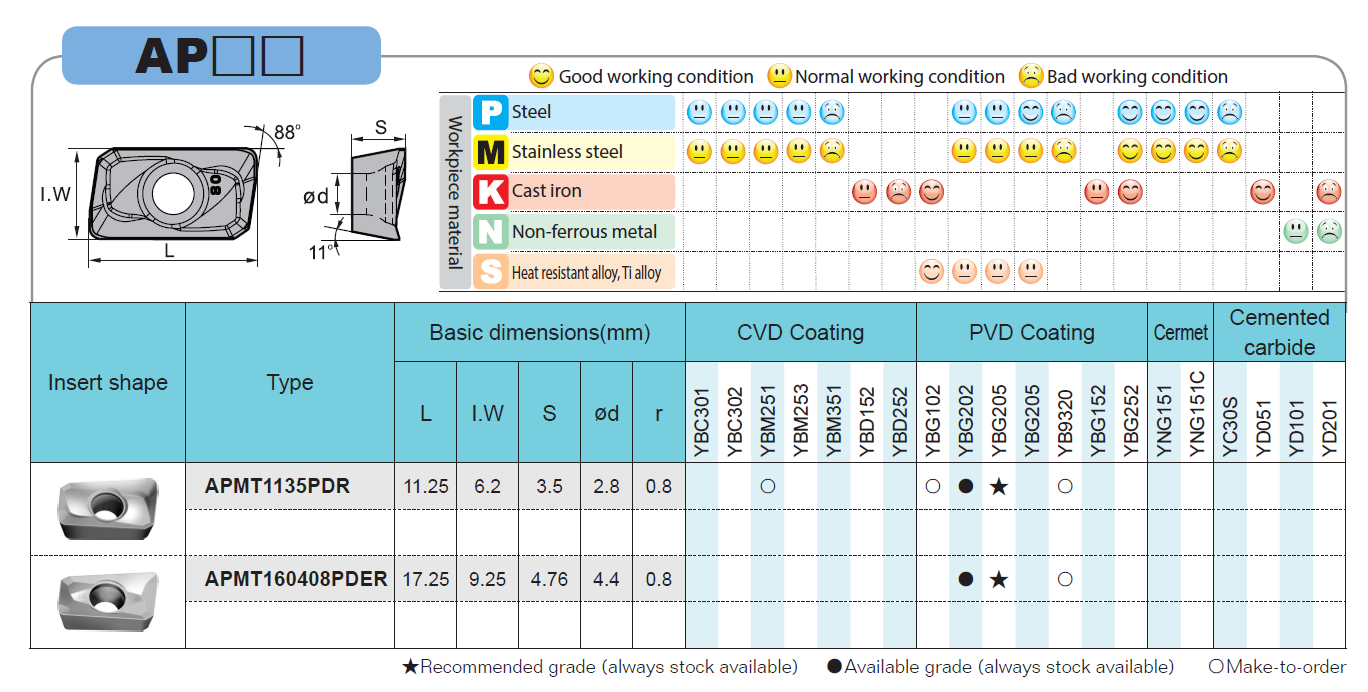

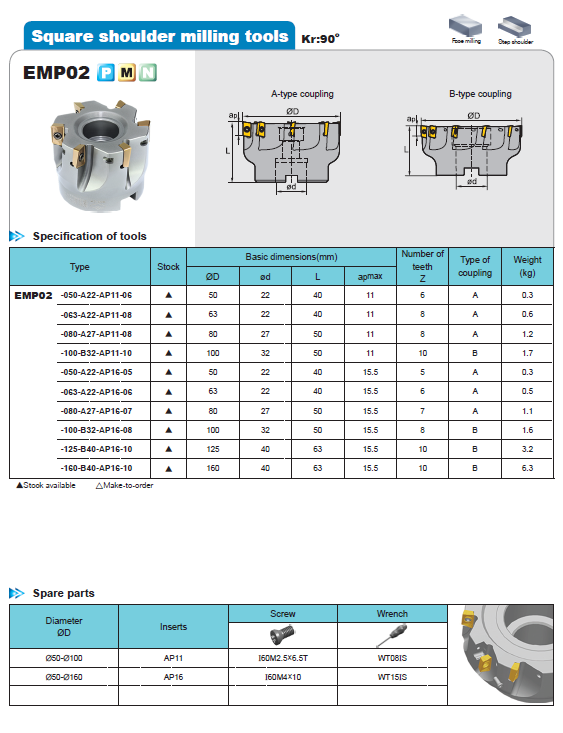

CNC milling insert APMT1604 for indexable milling tools

Short Description:

APMT1604 is a common cutting tool that is often used in machining processes such as turning, milling and drilling. Jingcheng Cemented carbide has an extensive selection of CNC threading inserts and tools with high-quality for your choice. We can assist you to choose the suitable cnc inserts according to your situations.

Coated Grade Introduction

YBG205

Ultra fine carbide substrate +Nano coating Suitable for finishing and semi-finish milling of P- and M- material

APMT1604PDER The APMT stands for the tool series, and 1604 stands for the size and shape of the tool. It usually made of hard alloy (Carbide). Carbide cutting tools have excellent hardness and wear resistance, suitable for high-speed machining and long-term use. Blade shape: Blades are usually square or diamond-shaped and have pointed cutting edges. Number of Edges: Depending on the specific model, blades may have single or multiple edges

Features

1. APMT1604 tools are often used in turning, milling, drilling and other processing techniques of metal materials. It can be applied to workpieces with different hardness and materials, including steel, aluminum alloy, cast iron, etc.

2. APMT1604 tool has good cutting performance, can provide higher cutting speed and longer life, reduce processing time and frequency of tool replacement

3. Please note that detailed product information (such as tool size, material, coating, etc.) may vary by supplier or manufacturer. Therefore, before purchasing or using any knives, it is recommended that you carefully read and follow the exact specifications and instructions provided by the knife manufacturer.

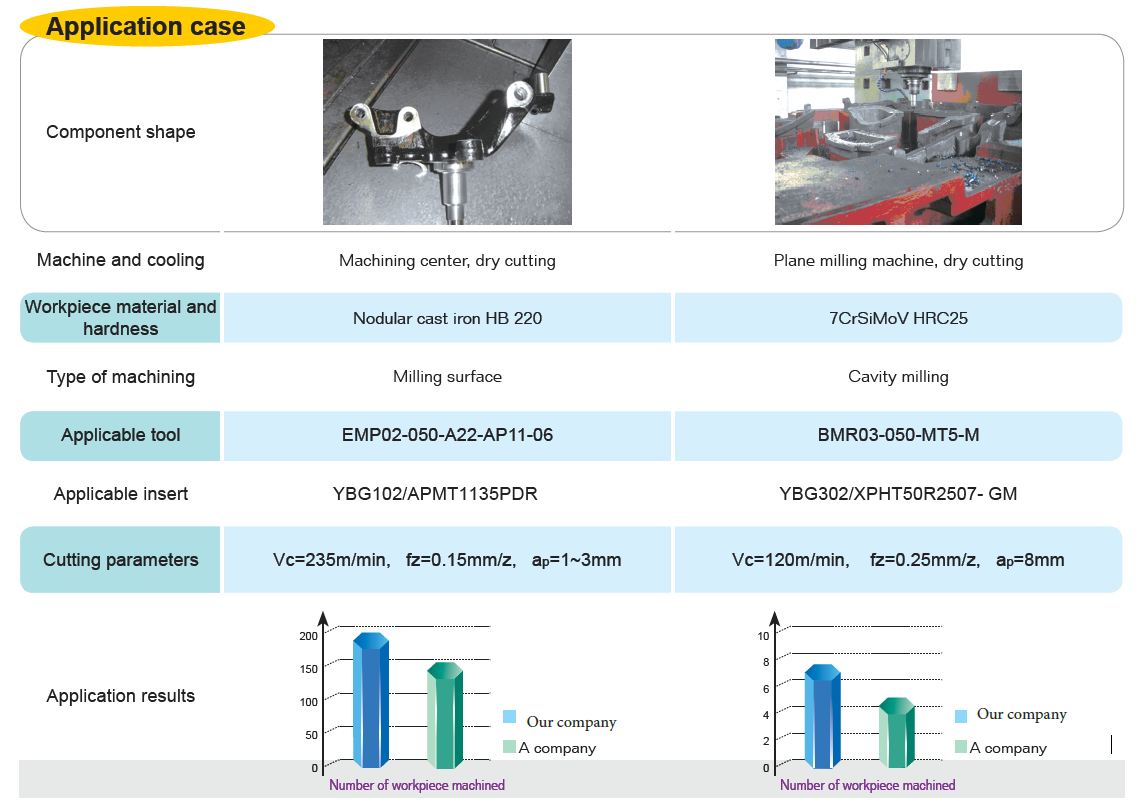

Test comparison of inserts abrasion

Parameter

Application

FAQ

Yes and we are doing OEM for many famous brand in the market.

We will send out products in no more than 5 days by courier.

If the type we have in stock, 1box will be OK.

Yes, we can customize for you as your requirements.

First, the workpiece material.

Second, dimension details:drill diameter, shank type, drilling depth, flute length and total length, cooling mode.

Third, if you need customized, offer us the drawing will be better.