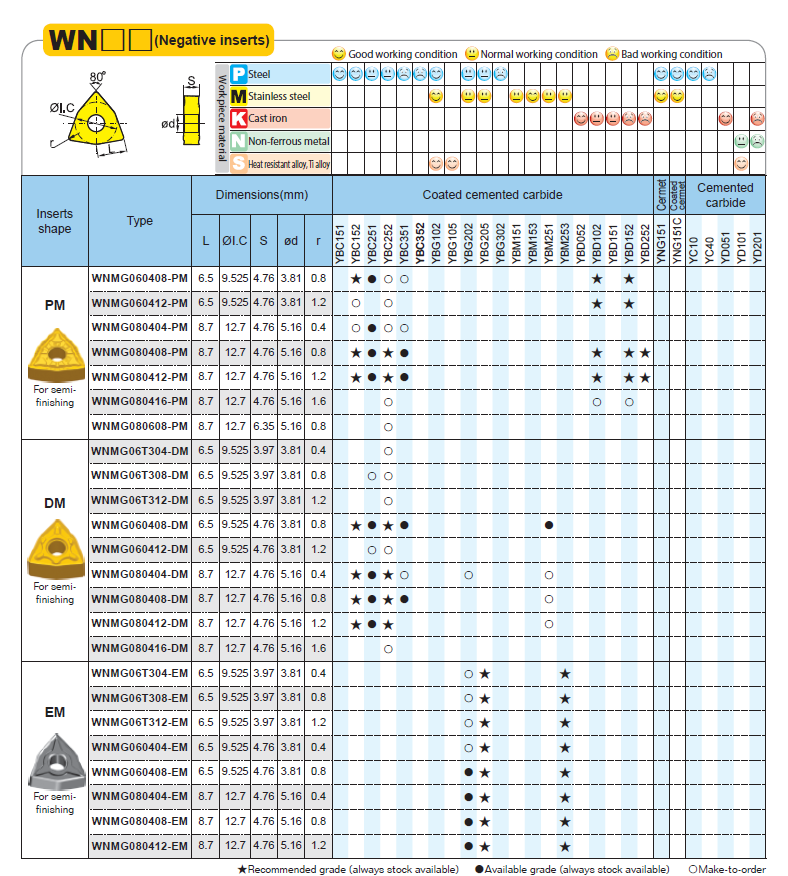

Cemented carbide CNC turning inserts

Short Description:

Black diamond inserts achieving both higher cutting speed and longer tool life. Jingcheng Cemented carbide has an extensive selection of CNC turning inserts and tools with high-quality for your choice. We can assist you to choose the suitable turning inserts according to your situations.

Coated Grade Introduction

YBC252

Comprising of thick TiCN and thick Al2O3 coatings, the grade has high capability against plastic deformation and good hardness of cutting edge. It is preferred grade for machining of steel from finishing to roughing. Under the same cutting conditions, the cutting speed can be increased by more than 25%, while the tool life can be 30% longer under the same cutting speed.

WNMG080408-PM is a standard tungsten carbide boring insert for turning and boring operations. This blade is made of high-quality tungsten carbide material, which has excellent wear resistance and corrosion resistance, and is suitable for processing on various materials.

Features

1. The insert is size 08 with 4 cutting edges each measuring 08mm and the cutting angle on the insert is 45 degrees.

2. This design allows the insert to provide a stable and efficient cutting effect during use.

3. WNMG080408-PM adopts a special coating process, which improves the heat resistance and hardness of the blade, making the blade more durable and long-lasting.

4. The coating also provides a lower coefficient of friction, reducing heat and tool wear during cutting, improving machining quality and efficiency.

5. It have a wide range of applications and are suitable for turning and boring of various steel materials, stainless steel, cast iron and high-temperature alloys.

6. It can be used on automated production lines as well as manually operated lathes and boring machines.

In summary, WNMG080408-PM is a high-quality, durable and efficient tungsten carbide boring insert for various machining applications, which can provide stable and high-quality cutting results.

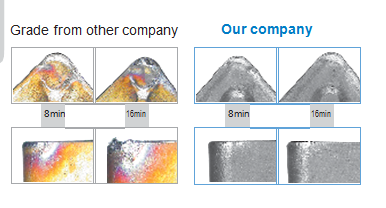

Test comparison of inserts abrasion

Parameter

Application

FAQ

Yes and we are doing OEM for many famous brand in the market.

We will send out products in no more than 5 days by courier.

If the type we have in stock, 1box will be OK.

Yes, we can customize for you as your requirements.

First, the workpiece material.

Second, the shape and dimension details.

Third, if you need customized, offer us the drawing will be better.