Tungsten Carbide Buttons For Drill Bits

Short Description:

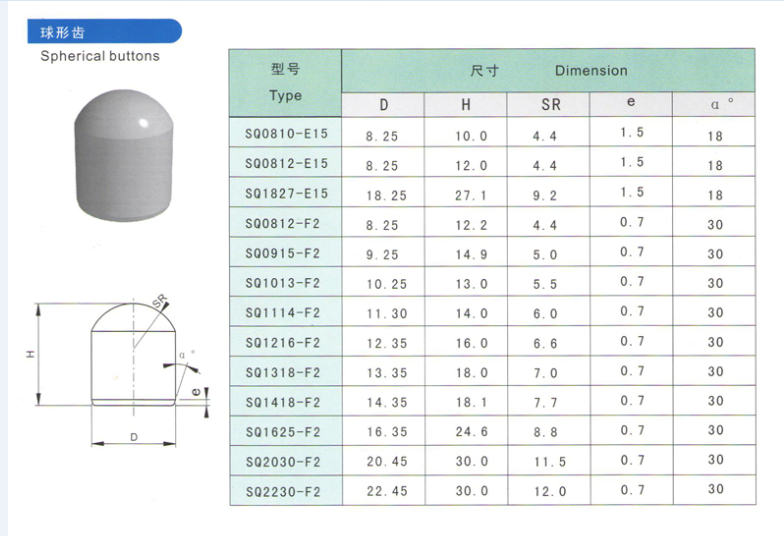

Tungsten Carbide Spherical Buttons for DTH Bits. Carbide button inserts suitable for many types of cemented carbide drill bit. We can help you choose the right tungsten carbide buttons.

Product Introduction

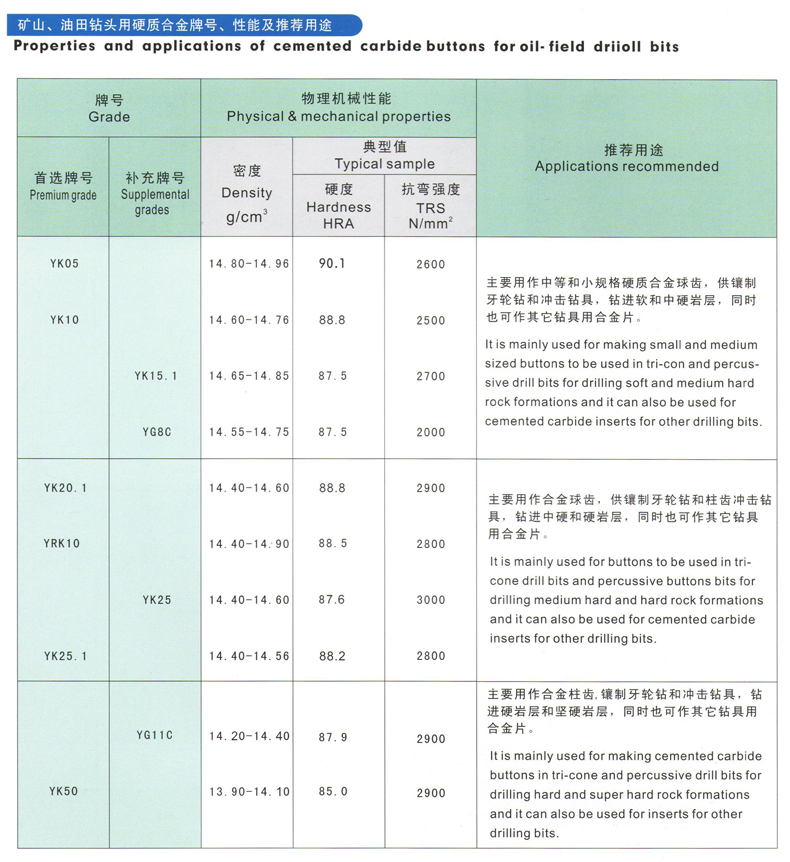

YK05:

It is mainly used for making small and mediumsized buttons to be used in tri-con and percussive drill bits for drilling soft and medium hard rock formations and it can also be used for cemented carbide inserts for other drilling bits.

Carbide button code key

S Q 12 12 A - E 15 Q

1 2 3 4 5 6 7 8

1 S-The series of buttons with a higher precision standard

2 Q-The shape of the top part of the button

Q: Spherical Z: Spherical cone T: Conical flat X: Wedge

B: Eccentric wedge S: Spoon F: Pointed claw J: Auger tip

3 The diameter of the button in mm. Only 2 integers are taken.(If the diameter is only one integer, then it is preceded by zero).

4 The height of the button in mm. Only 2 integers are taken.(fit is only one digit, then it is preceded by zero).

5 Special button top and it is omitted here.

6 The angle of chamfer at the bottom of the button.

E-It indicates the included angle in relation to the center line of the axis is 15° -18°

F-It indicates the included angle in relation to the center line of the axis is 30° (Exception:F2 indicates 0.7>30° )

G-lt indicates the included angle in relation to the center line of the axis is 45°

Xx-lt indicates the included angle in relation to the center line of the axis is other figures or other bottom shapes.

7 It indicates the height of the chamfer at the bottom and it is 10 times of the height in mm. If it is less than 2 inhtergers,

then it is preceded by zero.

8 It indicates air pocket structure at the bottom.

Q: Spherical hole z: Conical hole J: pointed hole It is omitted if there is no air pocket.

Note: If there are no positions of 6 and 7 or they are omitted, it belongs to the series of buttons with double chamfers .

Standard of tolerances of D and H

|

D(Diameter) |

H(Height) |

||

|

Nominal size |

tolerance |

Nominal size |

tolerance |

|

≤10

|

±0.10

|

≤11 |

±0.10 |

|

11~18 |

±0.15 |

||

|

>10

|

±0.15

|

18~25 |

±0.15 |

|

>25 |

±0.20 |

||

Grade instruction and application recommended

Parameters

FAQ

Yes, we can customize for you as your requirements.

Generally it is 3~5 days if the goods are in stock; or it is 10-25 days if the goods are not in stock, depending on order quantity.

Generally we don't provide free samples. But we can deduct sample cost from your bulk orders.

Always a pre-production sample before mass production; Always final Inspection before shipment.